The capacity and particle size range of a device can vary depending on the material used. If you need something more suitable for your needs, please get in touch with one of our engineers to customize it.

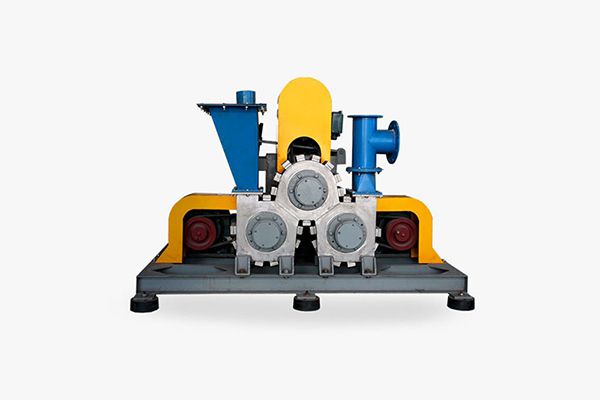

Surface modification is a common processing method necessary for turning regular incremental fillers into functional ones. Its primary purpose is to modify the surface area of mineral fillers. Using high energy mill to modify the materials with irregular shape, ultra-light, ultra-fine, viscosity or agglomeration with high degree of activation is an effective approach. To ensure successful modification, the material and additive dispersion must be taken into account while adhering to the outlined modification mechanism and process conditions.

The importance of selecting an independent modification process cannot be overstated. Critical process parameters include:

Improved results can be achieved by diluting, emulsifying, or adding a modifier in a spray. For an added boost, the modifier can be sprayed or dropped while the powder is continuously fed.

Improved results can be achieved by diluting, emulsifying, or adding a modifier in a spray. For an added boost, the modifier can be sprayed or dropped while the powder is continuously fed. Accurate measurement and even incorporation of enhancers and substances ensure that the proportions of the two substances are immediately precise.

Accurate measurement and even incorporation of enhancers and substances ensure that the proportions of the two substances are immediately precise. The temperature and timing must be correctly set to meet the requirements of the alteration process or the modifier specified for the process conditions, in order to guarantee that the alteration or coating reaction is effective.

The temperature and timing must be correctly set to meet the requirements of the alteration process or the modifier specified for the process conditions, in order to guarantee that the alteration or coating reaction is effective. Other factors include the use of auxiliary equipment, such as a beating machine or classifier, along with environmental aspects like temperature and humidity.

Other factors include the use of auxiliary equipment, such as a beating machine or classifier, along with environmental aspects like temperature and humidity.

Thank you for your long trust and company

Please fill out the form with your request. We will contact you as soon as possible.

-

- Inspection & Delivery Production processes are closely monitored in order to ensure that the products are adequately packaged and crated for both sea and land travel.

-

- Installation, Commissioning & Training Successful and dependable operation of any piece of equipment starts with proper installation, commissioning, and initiation.

-

- Process Upgrading & Optimization Process optimization is usually recommended after the system has been operating for a few years. New research discoveries, if utilized, can help to upgrade the process and bring positive changes to production.

-

- Quality Assurance ALPA has integrated ERP project management for synchronous engineering and streamlined production. We also improved management of supply chain maintenance, financial resource allocation, and human resources.